Y8-39,Y9-38 Type Boiler induced fan blower

1.The use of fans

The centrifugal induced fan of Y8-39 Y9-38 series boiler is designed by the fan energy saving group of the Ministry of Mechanical Industry, in order to make the inducer work in the high efficiency area and achieve the purpose of energy saving when the industrial boiler is in operation under different working conditions, and organizes the national fan industry famous person to design jointly. The high efficiency and energy saving products promoted by the State Economic Commission and the Ministry of Mechanical Industry have the advantages of high efficiency, low noise and broad suburbs with high performance curve.

The fan is suitable for the selection of 0.5 ~ 35t / h industrial boiler equipped with economizer (preheater) and smoke and dust removal device. All the air intake conditions are similar and the performance is suitable, but the maximum inlet temperature shall not exceed 250 ℃.

In order to reduce the dust content of the flue gas entering the fan, the dust removal device with dust removal efficiency not less than 85% must be installed before the induced fan, so as to reduce the wear of the fan and increase the service life of the fan.

2.Characteristics of Fan

The current industrial boiler series more, coal quality quality gap, with dust collector, economizer resistance, the required flow rate of fan, wind pressure difference. Considering the economy and adaptability of the wind turbine, it provides Y8-39 and Y9-38 type two series fan for users to choose the same connection. Two series of fan and installation of the same size.

3.Type of fan

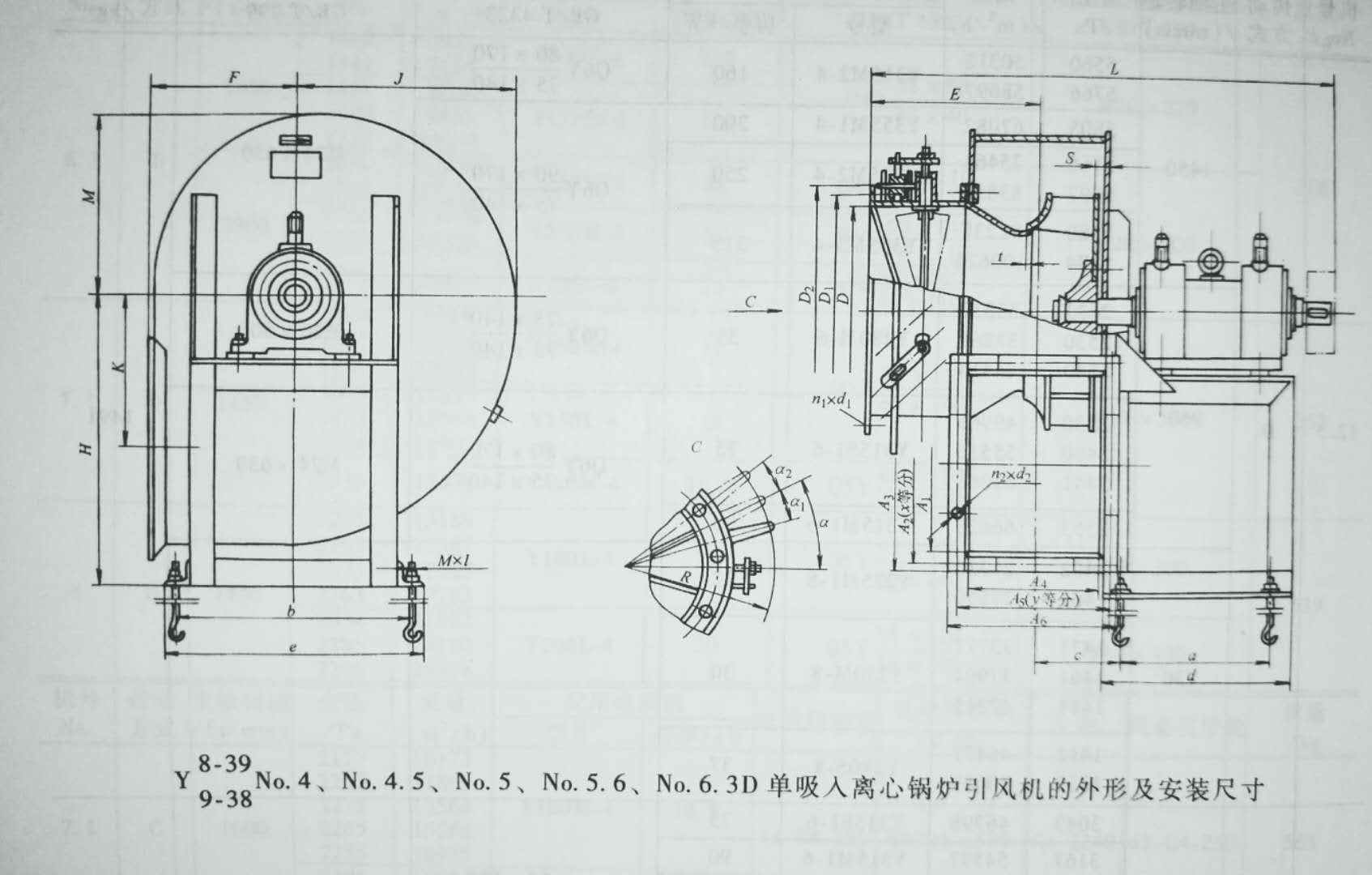

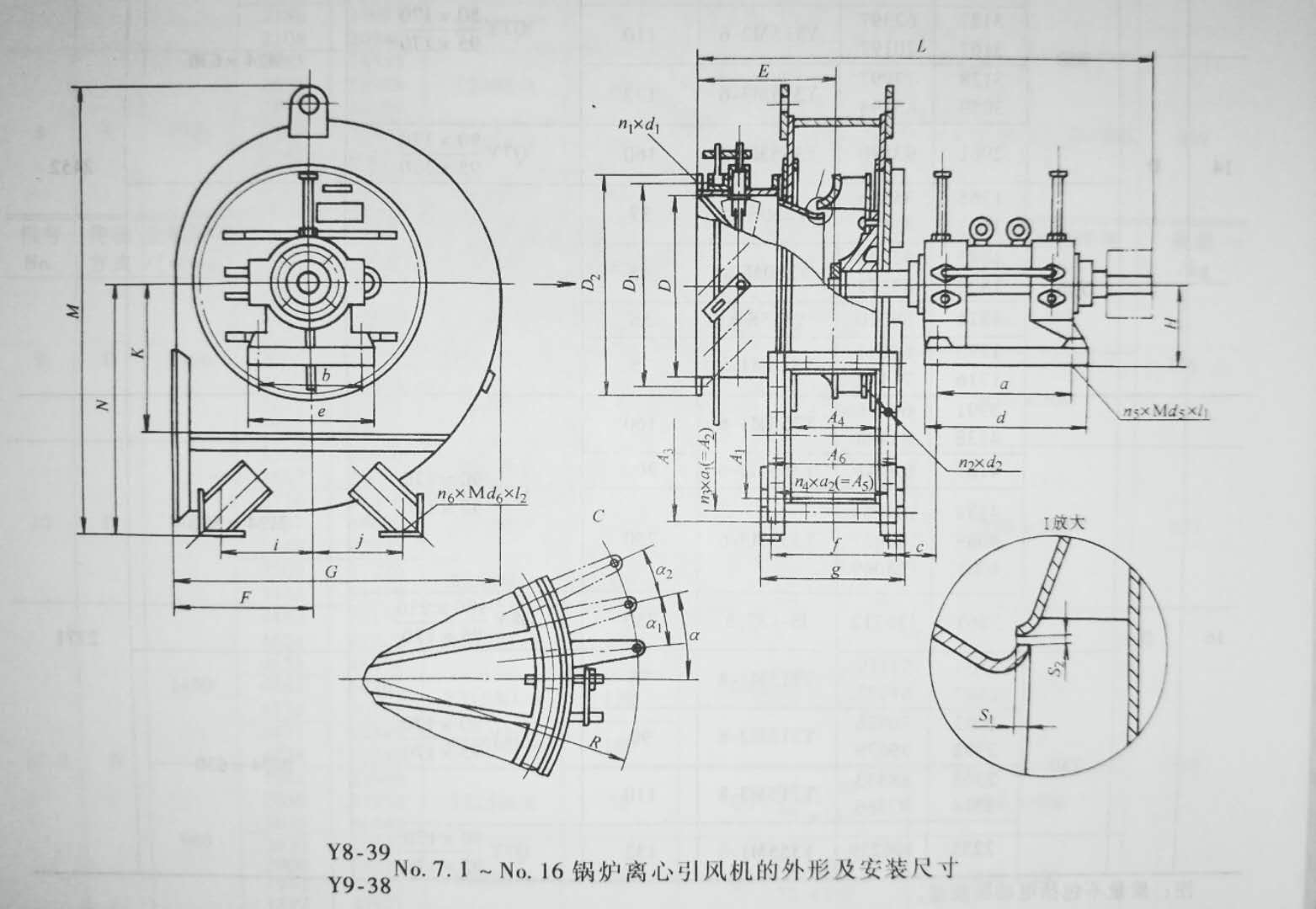

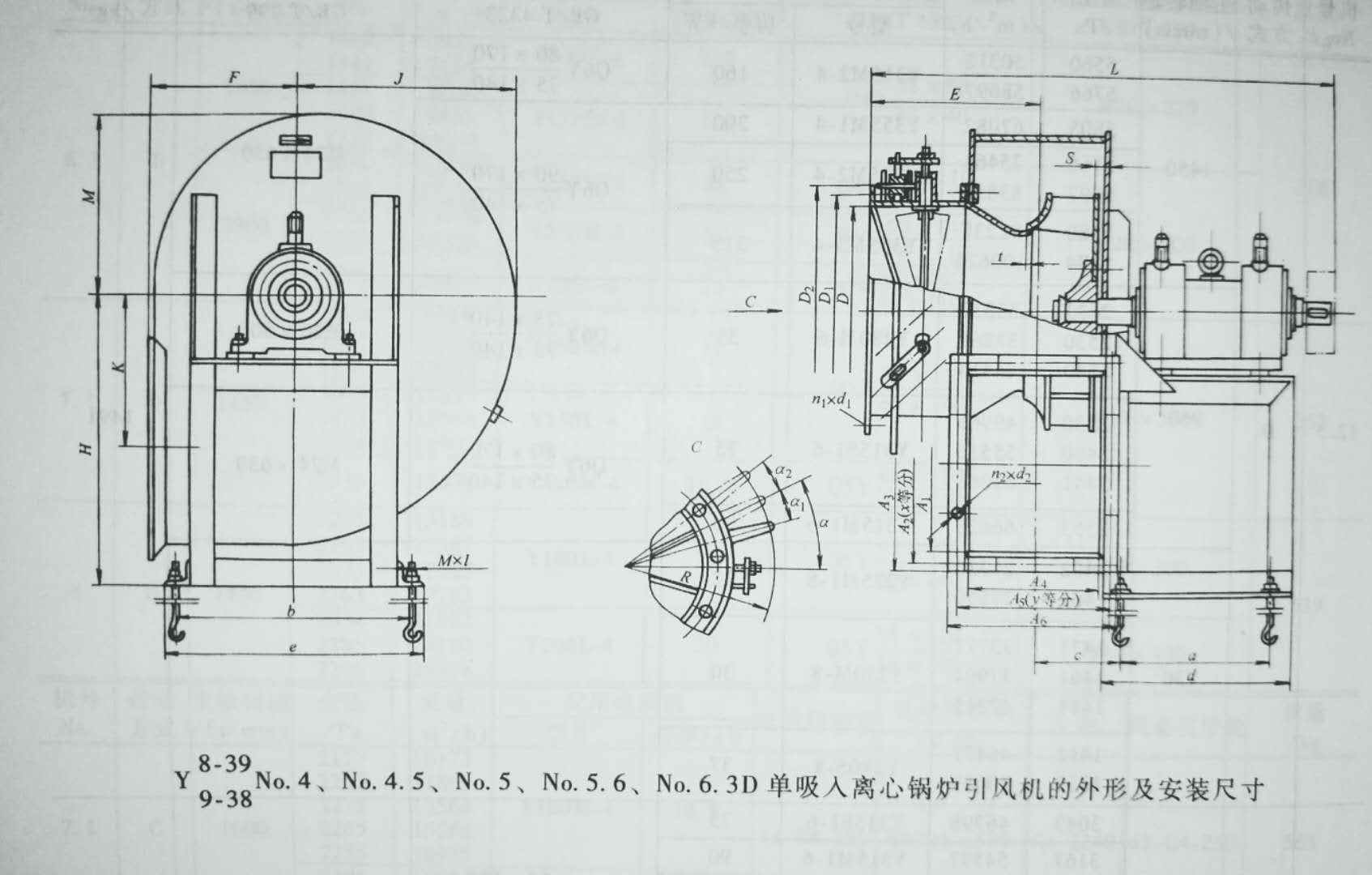

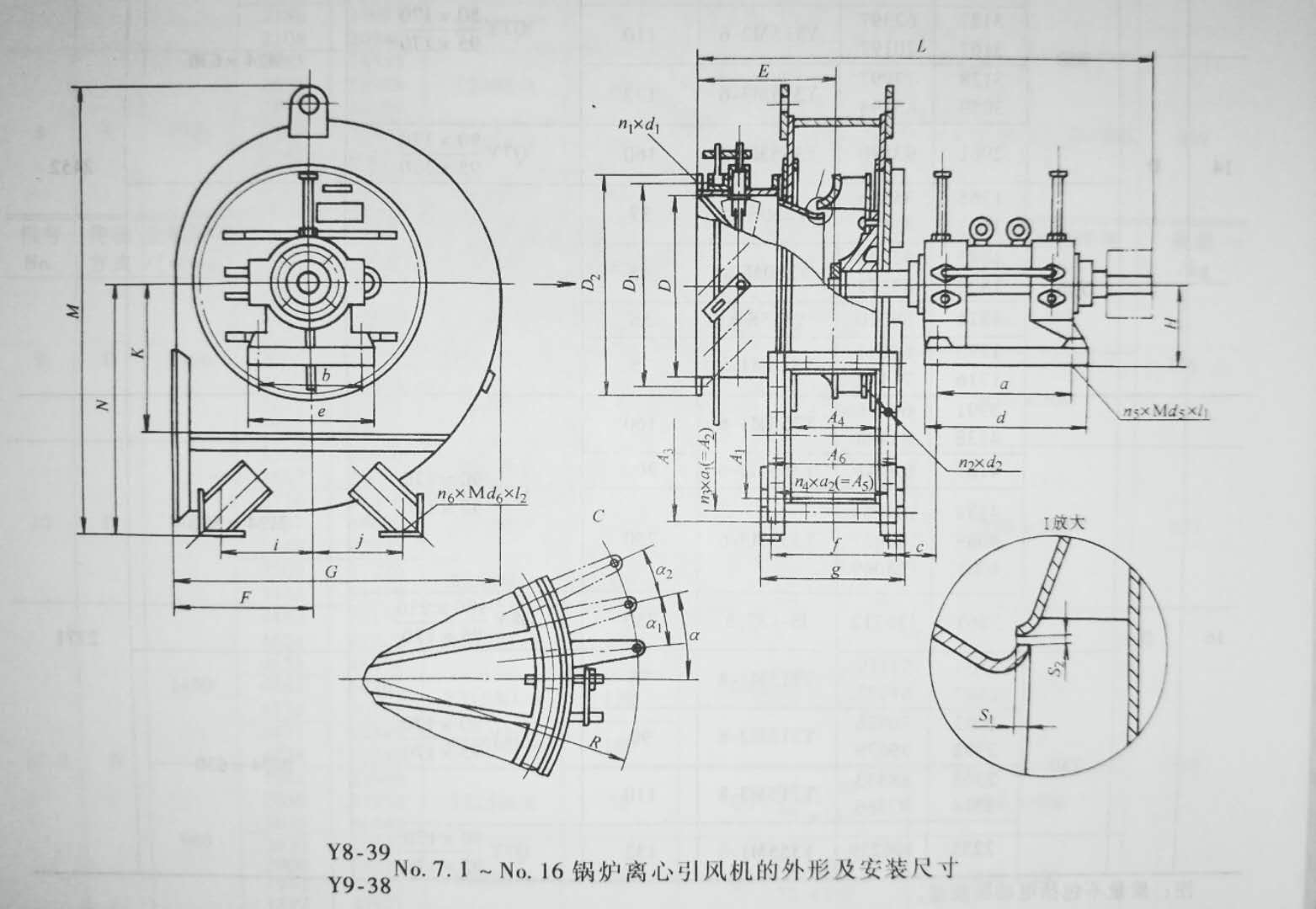

1. The fan is made into a single suction unit. The machine number is No4, No4.5, No5, No5.6, No6.3, No7.1, No8, No9, No10, No11.2, No12.5, No14, No16, number 13.

2. The fan can be made into clockwise rotation and counterclockwise rotation, and face the fan from the transmission part, for example, the impeller rotating clockwise is called the right-hand fan, which is expressed as right, and the left whirlwind machine is called left whirlwind machine.

3. The outlet position of the fan is expressed as the outlet angle of the casing. The right-handed fan and the left cyclone machine can be made into six angles of 0 °45 °45 °90 °135 °180 °180 °225 °. If you need other machine numbers or other angles, our factory has the strength to design and manufacture the "order" for you. Until you are satisfied.

4.Structure and characteristics

Fan by impeller, housing, air inlet, transmission group, adjustment door and other components.

1, impeller: the material is 16Mn. the long and short phase forward bending vane is welded between the arc conical front disc and the flat plate rear disk, the impeller is formed by strict static dynamic balance correction and overspeed operation test, so the operation is stable and reliable.

2, shell: cochlear shape is welded with steel plate. Ash removal door is opened on the cochlea plate, which is convenient to remove ash deposit in blade and shell. The balance and aerodynamic performance of impeller are guaranteed.

3, air inlet: a convergent streamline structure, fixed with bolts on the fan side.

4, transmission group: consists of spindle, water-cooled bearing box and coupling.

The main shaft is made of high quality steel and is made of rolling bearing. The bearing box has two forms: integral and dissected. No46.3.The integral bearing box No7.1C16 is used for split bearing box. Water cooling is required on both kinds of bearing boxes. The water consumption varies according to the working temperature and the ambient temperature, generally considered according to 0.5m / h. The bearing box is equipped with thermometer and oil level indication, the bearing box adopts 30 mechanical oil, and the oil quantity is carried out according to the oil standard.

5, adjusting door: used to adjust the flow of fan. The adjusting door is petal-petal-centering type, the axial direction is installed in front of the air inlet, the structure of external transmission is adopted, and the rotation is flexible and convenient. The adjustment range is from 90 °(totally closed) to 0 °(fully open). The position of the lever of the adjusting door is seen from the inlet direction to the right side. For the right rotating fan, the lever is pushed from the bottom up to the full open direction; the left rotary fan, In order to make the adjustment door work normally, it is necessary to do a good job of lubrication. It is suggested that the bentonite grease should be used at high temperature (260 ℃) so that the fan does not fail at high temperature.

Please contact us and get detailed Technical parameters and Drawings.

We could Design and Produce the Marine fan,Industrial Fan,and Other Ventilation Equipment according to your detailed requirement !

Please contact us and get detailed Technical parameters and Drawings.

We could Design and Produce the Marine fan,Industrial Fan,and Other Ventilation Equipment according to your detailed requirement !

- Previous Product:G9-37,Y9-37 Series Industrial Centrifugal blower fan for boiler

- Next Product:Y7-45 Seres Industrial boiler Air blower fan