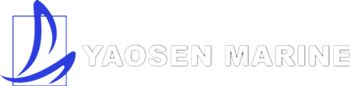

9-35,Y9-35 Series Boiler Industrial Supply fan,Exhaust fan

Summary

The service life of the type 9-35 single-suction boiler draft fan, although of the older type, is considerable. It is mainly applicable to 2t / h 230t / h, steam boiler ventilation system. The basic type of ventilator is "9-35" and the type of induced fan is Y9-35, in which:

9- denotes the integer of the total pressure coefficient multiplied by 10 at the maximum efficiency (η max) point of the fan.

35-an integer representing the specific rotation of the fan at the maximum efficiency (η max).

Y- means an induced fan.

Single suction fan supplementary model "11" or "12", in which the first digit 1 for single inhalation, the second digit for design sequence number.

There are 13 kinds of basic machine number: No6D5D8D10D10D10DC135D 15.5 DX 15.5 FG 15.5 FN 20FU 21.5 F. if the above machine number and transmission mode can not meet your requirements, our factory has the ability to design and manufacture non-standard products for you to meet your production needs.

From the direction of the motor face impeller, clockwise rotation called right-hand fan, as "right", on the contrary, said left whirlwind machine as "left".

Junction structure

The fan is mainly made up of impeller, casing, inlet, transmission group and adjusting door.

Impeller-made of forward curved blade, conical cap and plate rear disc welded, riveted on shaft disk, the maximum speed of impeller can be up to 80 m / s after strict static and dynamic balance correction and overspeed test.

Housing-made of cochlear shape No6 and No12 blower welded by steel plate, the integral structure is made of no 13. 5 or more with 1/4 casings over which can be disassembled in order to fit or remove impellers.

Transmission set-Spindle is made of high quality steel, single suction fan is roller bearing, bearing box is equipped with thermometer and oil level indicator to indicate the amount of oil and bearing temperature.

Regulating door-made of ordinary steel plate, used to adjust air volume and control motor load, generally for adjusting petal adjusting door.

Installation of wind turbine

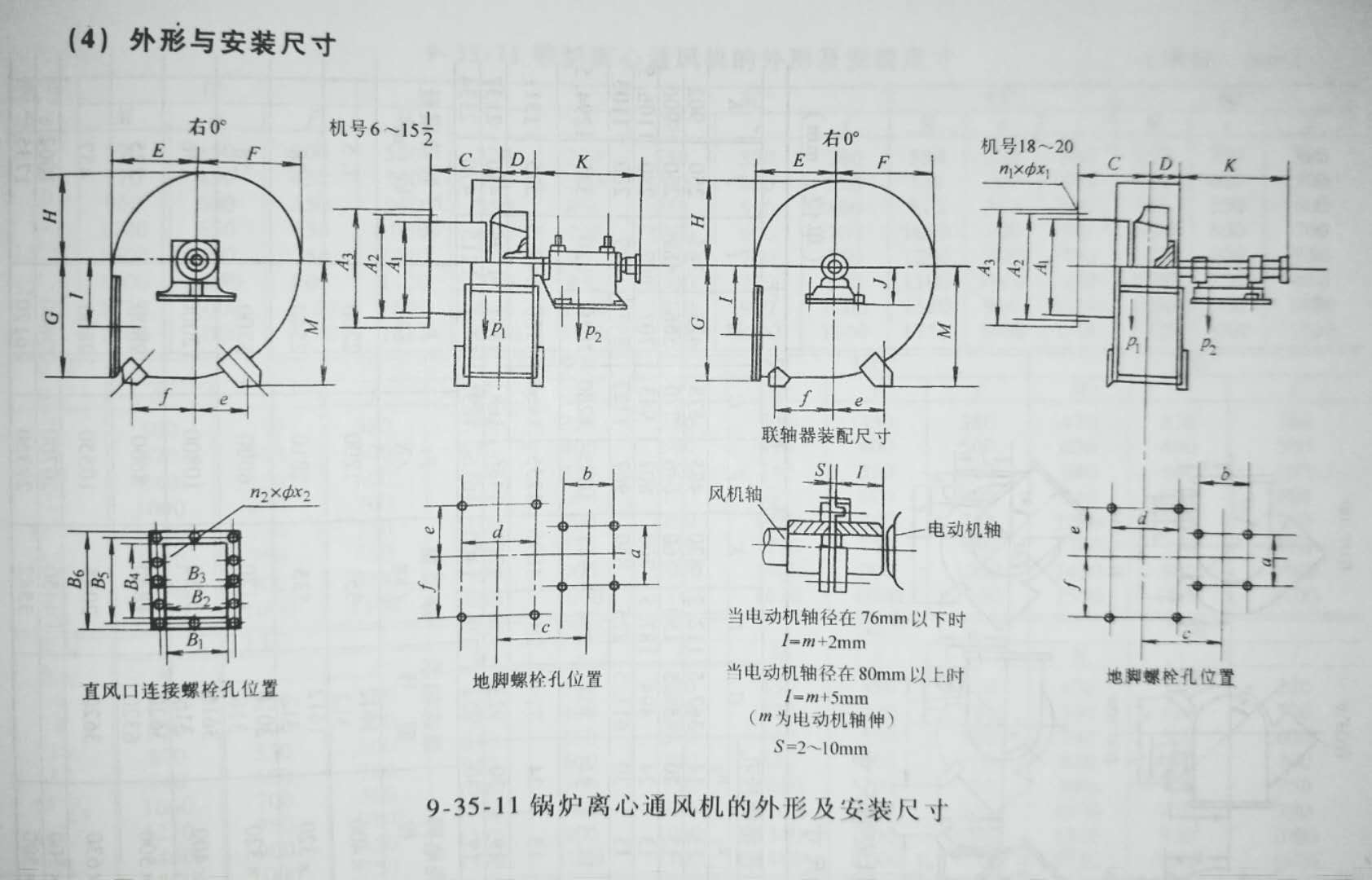

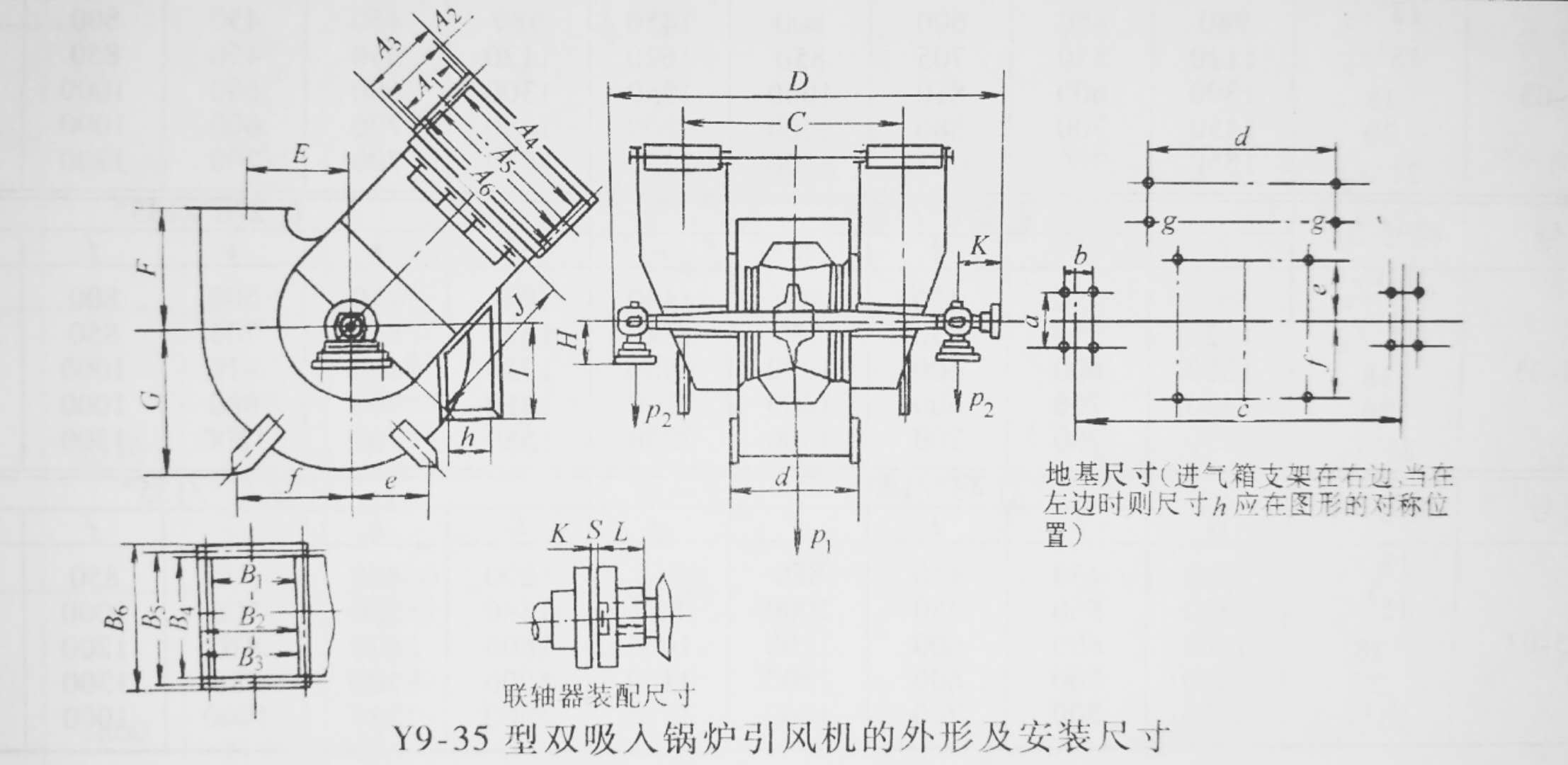

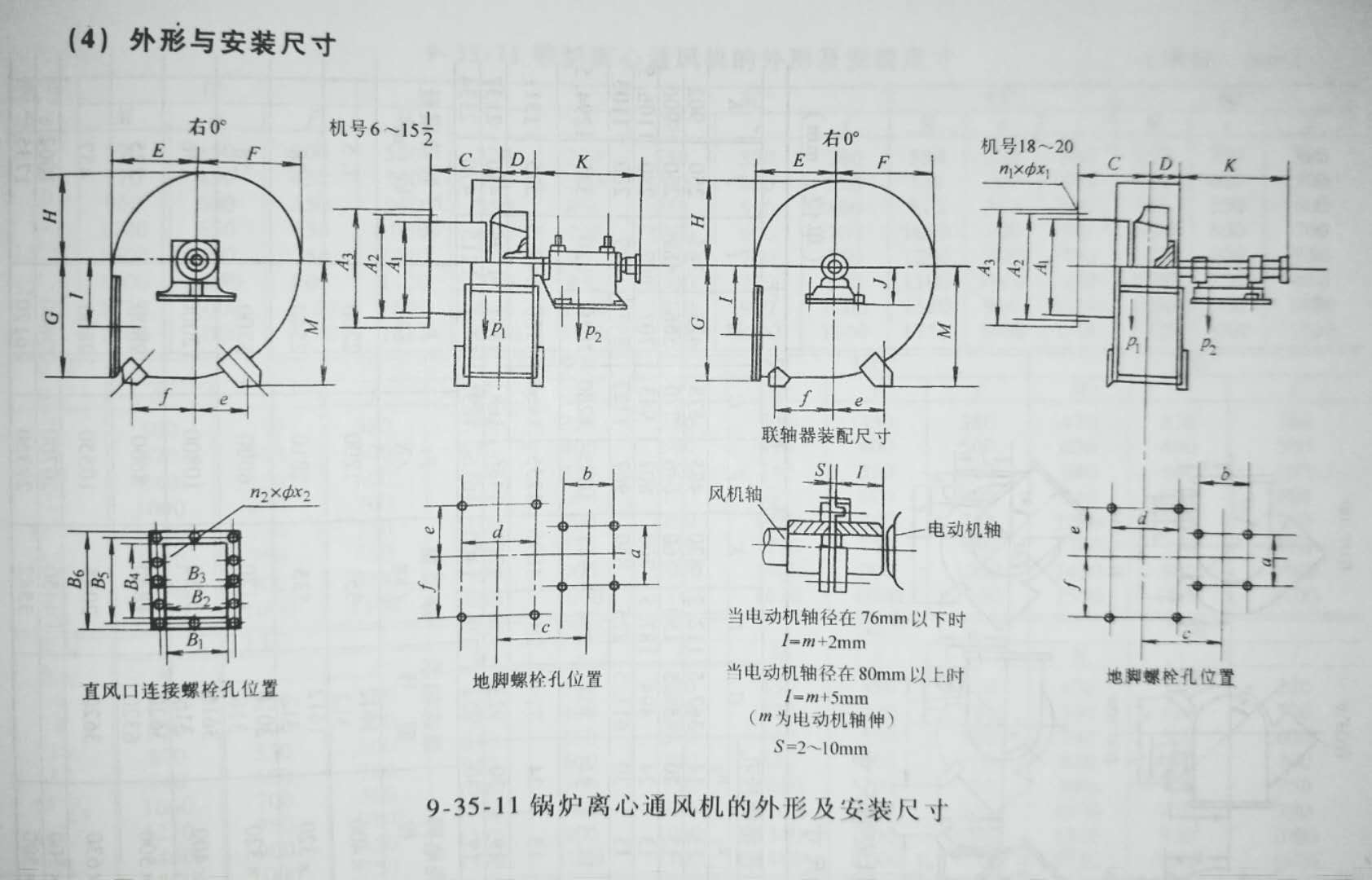

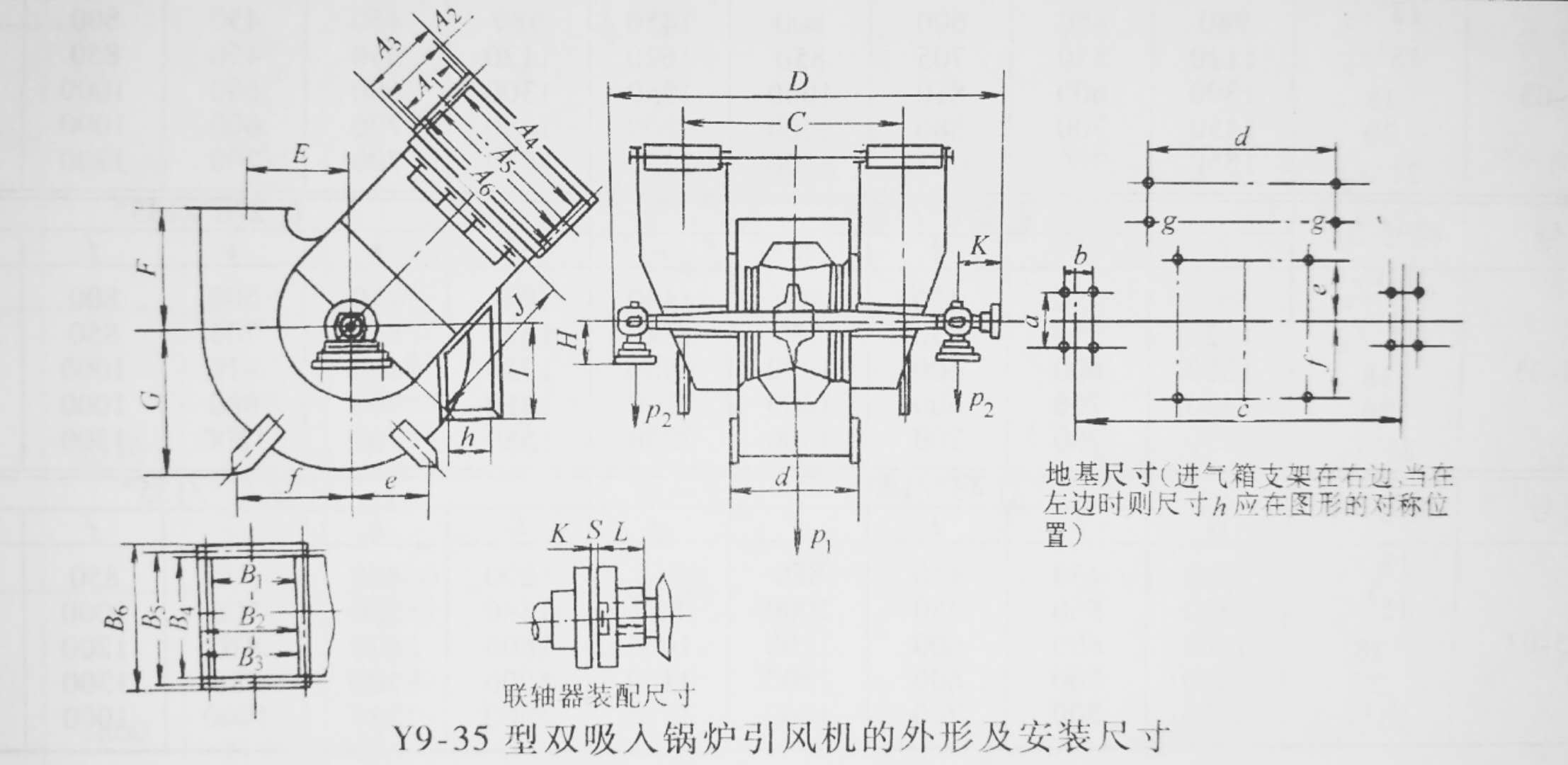

The concrete base of the fan shall be designed and manufactured according to the shape and dimensions of the fan and motor before installation

Manufacture and install necessary parts and tools, such as anchor bolts, safety covers, etc.

Each department should be carefully checked, cleaned, cleaned and cleaned with kerosene before installation

Inside the box, add lubricating oil, if any damage, should be repaired.

First install the casing on the base, pay attention to the weight and thermal expansion and load of the pipeline should not be

Add it to the housing.

Remove the detachable parts of the housing and install the impellers and the drive parts on the basis,

Check each clearance size as required and maintain the horizontal state of the shaft.

At the inlet of the fan, if the line is not connected, the barbed wire shall be installed.

Self-contained by the user.

Install motor, make motor shaft and fan axis concentric, axis discentricity is 0.05 mm.

The coupling shall be fitted with a safety cover designed and manufactured by the user according to the actual situation.

Air turbine operation

The following preparations should be made before the machine starts:

Close the inlet air regulating valve, and the outlet air regulating valve slightly open.

We check the machine parts clearance, the rotating part does not allow Guaceng, all parts should be fixed

It should be tightened.

Check whether the coupling is installed reliably.

4 check the electrical circuit and instrument is correct.

Check that the rotating direction of the impeller is consistent with the sign.

According to the actual situation, the user should decide whether or not to use the starting equipment of the motor.

In the operation of fan system, we should pay close attention to abnormal phenomena such as abnormal sound, abnormal earthquake, abnormal smell and so on.

It should be excluded.

When running to normal speed, gradually open the inlet air regulating valve, and adjust the outlet air regulating valve, straight

Until the prescribed load is met.

After one or two hours of running the machine, stop and check the bearings and other parts, and then run for another 6 to 8 hours.

If the situation is normal, can be delivered to the acceptance of the use.

Bearing temperature not to exceed 40 ℃ in operation

Parking shall be carried out in the following order:

Close the inlet air valve and open the outlet air valve slightly.

Turn off the motor in accordance with the regulations.

In the next instance, the stop check must be made immediately.

There is a loud noise

The bearing temperature rises sharply.

Severe vibration or impact of the body.

Maintenance of wind turbine

Fans and their systems are not allowed to run with disease.

The fan should be kept and used by special person.

Regular removal of dust, dirt and other impurities in the fan, and prevent rust.

Fan maintenance must be carried out during shutdown.

Fan maintenance, test-run prohibited children and unrelated personnel and people with disabilities to watch.

No one is allowed to stand within ten meters of the inlet and outlet direction of the fan when the fan is being tested.

Inventory tools and other supplies before and after fan maintenance to prevent them from remaining inside the fan and plumbing.

Main faults and causes of Fan

Violent vibration of bearing box

The fan shaft is not concentric with the electric shaft, and the coupling is askew;

Friction between housing and impeller or inlet and impeller;

The stiffness of the foundation is not enough or firm;

Impeller rivet loosening or impeller deformation;

Impeller shaft disc hole and shaft fit loosening;

Housing, bearing box and support, bearing seat and bearing box cover and other connection bolts loose;

The blower enters, the outlet pipe installs badly, produces the resonance;

Rotor unbalance;

Fan blade wear.

Bearing temperature rise is too high

Violent vibration of bearing box;

Poor quality lubricant, deterioration or containing dust, sand, dirt and other impurities;

Bearing box cover, seat connection bolt tight force is too big or too small;

Shaft and rolling bearing installation askew, before and after the two bearings are not concentric;

Rolling bearing damage or shaft bending.

Motor current is too high or temperature rise is too high

The intake duct gate is not closed when driving;

The flow exceeds the specified value;

The density of the gas conveyed by the fan is too large or has a sticky substance.

Low input voltage or single-phase power failure;

The coupling is not straight, the leather ring is too tight or the clearance is not even;

Affected by the violent vibration of the bearing box.

Please contact us and get detailed Technical parameters and Drawings.

We could Design and Produce the Marine fan,Industrial Fan,and Other Ventilation Equipment according to your detailed requirement !

Please contact us and get detailed Technical parameters and Drawings.

We could Design and Produce the Marine fan,Industrial Fan,and Other Ventilation Equipment according to your detailed requirement !

- Previous Product:FG Series boiling Boiler ventilation Fan

- Next Product:Y9-19,Y9-26 Series Industrial bolier high pressure supply fan