SDS series Tunnel jet fan

SDS series jet fan from 630 mm to 1600mm, which is divided into two categories: unidirectional axial fan and reversible (two-way) axial flow fan. The maximum thrust is 3 500 Ns. The high efficiency and low noise fan can be selected for any load and working condition.

The SDS series jet fan adopts advanced technology to obtain good quality assurance. The fan shell is formed by spinning flanging with special machine tool imported from the United States, and the inner wall of impeller section is machined by gold, which ensures the coaxial degree and strength of the casing. The radial clearance of the blade is ensured, the exterior is treated by hot dip galvanizing or other equivalent coating, the appearance is beautiful and anticorrosion, the performance is excellent. The fan blade and hub are processed into the die casting cavity by the automatic NC boring and milling machining center of Toshiba Company of Japan. High (low) die casting of aluminum alloy was carried out in high pressure casting and low pressure casting machine respectively. Through highway tunnel, railway tunnel, water conservancy dam project, etc.The performance index, corrosion resistance, reliability, economy, quality requirement and economic index of the fan can be used in all kinds of tunnels.

3. Semi-lateral ventilation system: this system can be divided into two types: supply type semi-transverse ventilation mode and exhaust type semi-lateral ventilation mode. Ventilation system for tunnels.

4 factors to be considered in tunnel ventilation system: project A investment in B power capacity C operation cost D air quality E safety factor F guarantee measures mentioned above. After the factor economy synthesis establishes the optimization plan

5, the tunnel ventilation system ventilator quantity, Factors of machine number selection: ACON x and smoke concentration B vehicle flow (vehicle)Density, speed) C wind load (tunnel length * width * height) D emission (age, quantity) E emergency measures in case of fire.

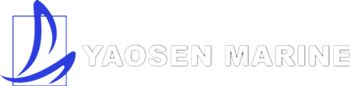

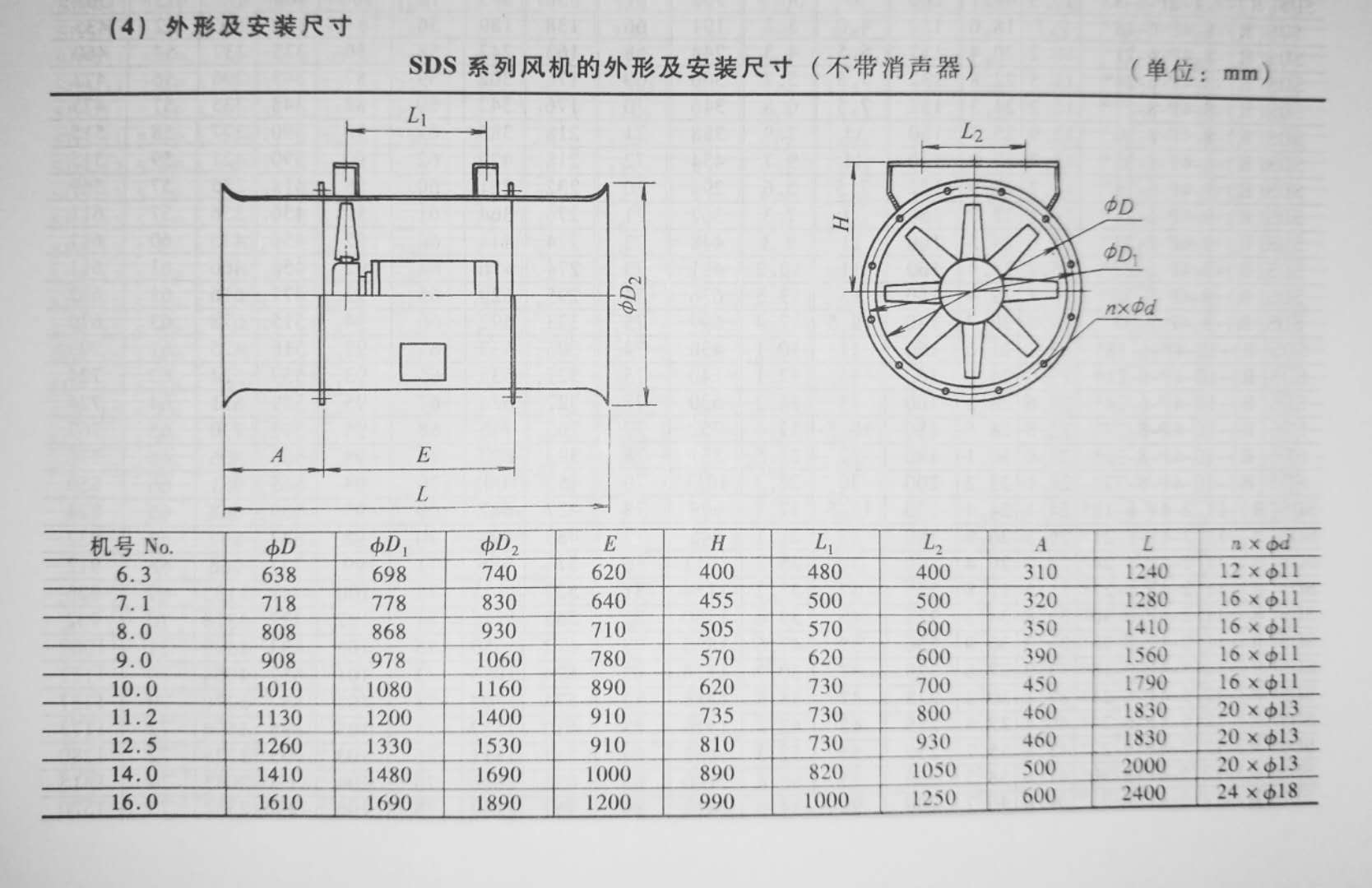

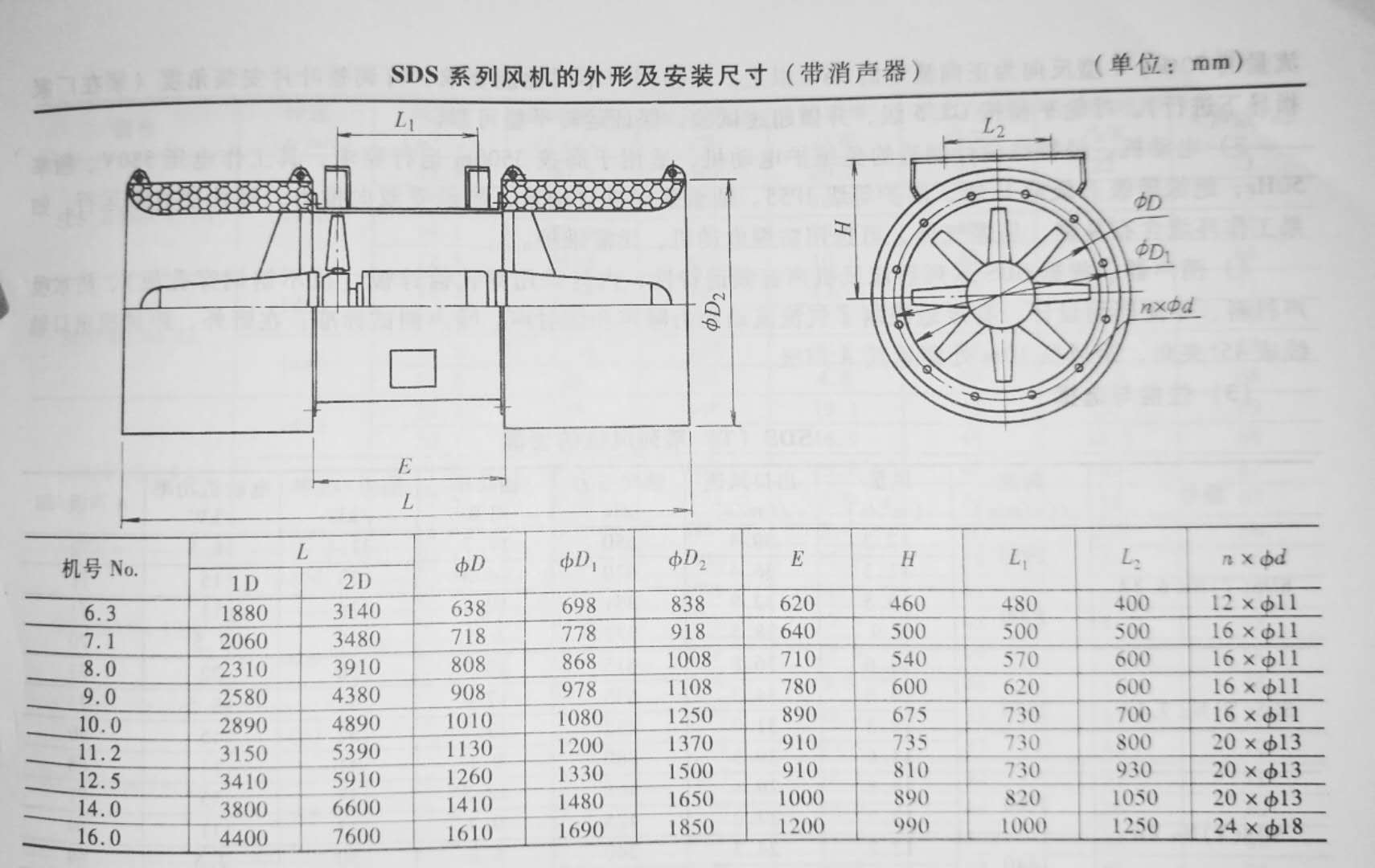

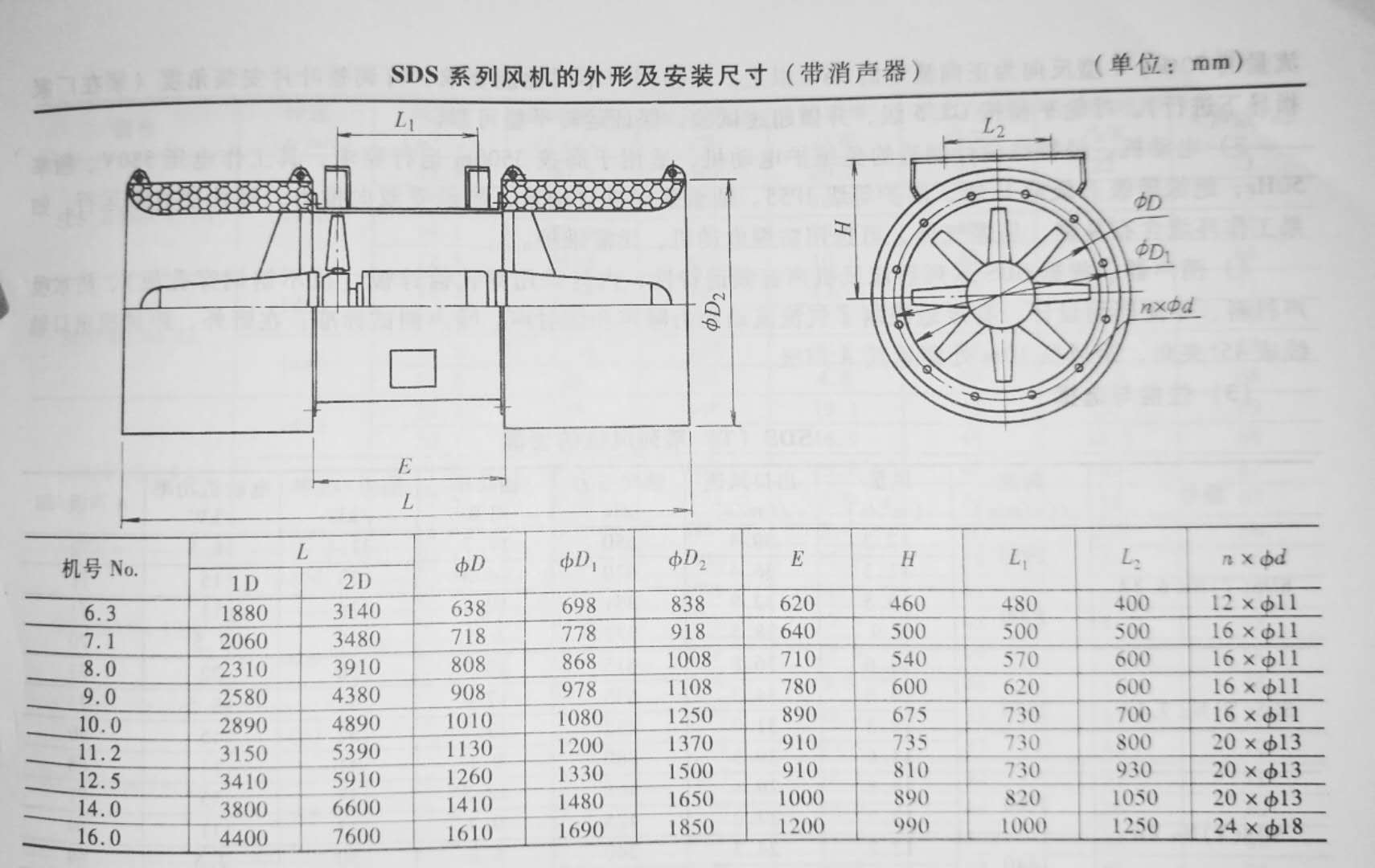

6. The structural characteristics of tunnel ventilation system using ventilator the tunnel type fan is divided into two types: one way jet fan (SDS) and two direction jet fan [SDS (R)] ventilator body, muffler, Bracket foot: automatic welding and mechanism forming of steel plate, surface coating treatment, To ensure the fan strength and anti-corrosion fan impeller: in order to meet the need of tunnel ventilation, SDS series fans can change the number of blades and change the fan blade angle muffler: the length of muffler is usually twice the diameter of fan, when the noise requirement is high, Can also take two times the diameter of the fan, muffler and fan bodyBolt fixed. The matching motor: SDS series jet fan is completely enclosed in squirrel cage, the motor is equipped with flange mounting disc, and the insulation grade of motor is H grade. Corrosion protection grade IP55, motor leading cable can be connected to fan body housing junction box, motor with lubricating grease nozzle, external metal hose connected to fan body housing lubricating grease nozzle. Fan reversible switching time: under a state of emergency, The forward and negative switching time of the jet fan is very important. There are two switching methods of the jet fan, electronic and mechanical, which can be switched to the rated speed of the fan within 30 seconds.

The SDS series jet fan adopts advanced technology to obtain good quality assurance. The fan shell is formed by spinning flanging with special machine tool imported from the United States, and the inner wall of impeller section is machined by gold, which ensures the coaxial degree and strength of the casing. The radial clearance of the blade is ensured, the exterior is treated by hot dip galvanizing or other equivalent coating, the appearance is beautiful and anticorrosion, the performance is excellent. The fan blade and hub are processed into the die casting cavity by the automatic NC boring and milling machining center of Toshiba Company of Japan. High (low) die casting of aluminum alloy was carried out in high pressure casting and low pressure casting machine respectively. Through highway tunnel, railway tunnel, water conservancy dam project, etc.The performance index, corrosion resistance, reliability, economy, quality requirement and economic index of the fan can be used in all kinds of tunnels.

The use of the product indicates that in the construction of subway, highway tunnel, railway tunnel and other basic projects, the air quality standard and safety factors depend on the ventilation system to meet the requirements. As far as the ventilation system is concerned, it is necessary to maintain good air quality for a long time. Otherwise, it is harmful to human body.

Traffic tunnels can be divided into three categories in principle: subway, highway tunnel and railway tunnel.

The tunnel ventilation system may have three basic modes or may be mixed.

1. Longitudinal ventilation system: this is the most basic way of ventilation. Fresh air flows from the tunnel inlet to the outlet, There is no need to install ventilation ducts along the longitudinal direction of the tunnel. This ventilation mode is generally adopted with a reversible jet fan. The fan is installed on the top or side of the tunnel and can be fully ventilated in both directions. In order to achieve two-way ventilation or control smog, if the tunnel is longer, it must be attached to the central supply, exhaust shaft, shaft connected to the atmosphere to form a mixed ventilation mode.

2. transverse ventilation system: along the tunnel is arranged in the direction of delivery, exhaust duct, central fresh air from the wind Pavilion collection, centralized exhaust excluded from the tower of the wind, the general will air set on the road below, the exhaust duct is arranged in the upper lane, air duct and the exhaust duct intervals is sent, the air outlet, the tunnel cross section in time. The wind along the under accident conditions, the extraction of smoke.

The tunnel ventilation system may have three basic modes or may be mixed.

1. Longitudinal ventilation system: this is the most basic way of ventilation. Fresh air flows from the tunnel inlet to the outlet, There is no need to install ventilation ducts along the longitudinal direction of the tunnel. This ventilation mode is generally adopted with a reversible jet fan. The fan is installed on the top or side of the tunnel and can be fully ventilated in both directions. In order to achieve two-way ventilation or control smog, if the tunnel is longer, it must be attached to the central supply, exhaust shaft, shaft connected to the atmosphere to form a mixed ventilation mode.

2. transverse ventilation system: along the tunnel is arranged in the direction of delivery, exhaust duct, central fresh air from the wind Pavilion collection, centralized exhaust excluded from the tower of the wind, the general will air set on the road below, the exhaust duct is arranged in the upper lane, air duct and the exhaust duct intervals is sent, the air outlet, the tunnel cross section in time. The wind along the under accident conditions, the extraction of smoke.

3. Semi-lateral ventilation system: this system can be divided into two types: supply type semi-transverse ventilation mode and exhaust type semi-lateral ventilation mode. Ventilation system for tunnels.

4 factors to be considered in tunnel ventilation system: project A investment in B power capacity C operation cost D air quality E safety factor F guarantee measures mentioned above. After the factor economy synthesis establishes the optimization plan

5, the tunnel ventilation system ventilator quantity, Factors of machine number selection: ACON x and smoke concentration B vehicle flow (vehicle)Density, speed) C wind load (tunnel length * width * height) D emission (age, quantity) E emergency measures in case of fire.

6. The structural characteristics of tunnel ventilation system using ventilator the tunnel type fan is divided into two types: one way jet fan (SDS) and two direction jet fan [SDS (R)] ventilator body, muffler, Bracket foot: automatic welding and mechanism forming of steel plate, surface coating treatment, To ensure the fan strength and anti-corrosion fan impeller: in order to meet the need of tunnel ventilation, SDS series fans can change the number of blades and change the fan blade angle muffler: the length of muffler is usually twice the diameter of fan, when the noise requirement is high, Can also take two times the diameter of the fan, muffler and fan bodyBolt fixed. The matching motor: SDS series jet fan is completely enclosed in squirrel cage, the motor is equipped with flange mounting disc, and the insulation grade of motor is H grade. Corrosion protection grade IP55, motor leading cable can be connected to fan body housing junction box, motor with lubricating grease nozzle, external metal hose connected to fan body housing lubricating grease nozzle. Fan reversible switching time: under a state of emergency, The forward and negative switching time of the jet fan is very important. There are two switching methods of the jet fan, electronic and mechanical, which can be switched to the rated speed of the fan within 30 seconds.

Please contact us and get detailed Technical parameters and Drawings.

We could Design and Produce the Marine fan,Industrial Fan,and Other Ventilation Equipment according to your detailed requirement ! - Previous Product:SDS-II Series Tunnel low noise jet fan

- Next Product:SDF Series low noise Tunnel Jet Fan